Starting a sunglasses brand is an exciting journey, but one of the most critical decisions you’ll make is choosing the right manufacturer. The global sunglasses market, valued at $23.52 billion in 2023 and growing at a 5.6% annual rate according to market research, presents tremendous opportunities for new and established brands alike. However, partnering with an unreliable manufacturer can lead to subpar products, delayed timelines, and a tarnished reputation. So, how do you find an expert sunglasses manufacturer that aligns with your vision and delivers exceptional quality?

This comprehensive guide will walk you through every step of the process, from understanding manufacturing options to vetting potential partners. Whether you’re launching a startup or scaling an existing brand, you’ll find actionable insights to select a manufacturer that offers customization, reliability, and value. For a proven example, consider GM SUNGLASSES, a China-based leader with nearly a decade of experience, serving over 60 countries with stylish, high-quality eyewear.

In this article, we’ll explore OEM vs. ODM options, how to define your brand’s needs, current market trends, customization strategies, quality assurance, budgeting, and more. With over 2,000 words of detailed advice, this guide ensures you have everything you need to make an informed decision. Let’s get started on finding the perfect manufacturing partner for your sunglasses brand.

OEM vs. ODM: Understanding Your Manufacturing Options

Before you begin your search, you need to decide how much control you want over your sunglasses’ design and production process. The two primary manufacturing models are OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). Understanding these options will shape your approach, so let’s dive into the details.

What is OEM?

With OEM, you provide the sunglasses design, and the manufacturer produces it according to your specifications. This option is ideal if you have a unique vision or a design team ready to create something bespoke. For example, if your brand focuses on bold, innovative styles like Bold Rectangular Frames, OEM allows you to dictate every detail—frame shape, lens type, and materials.

What is ODM?

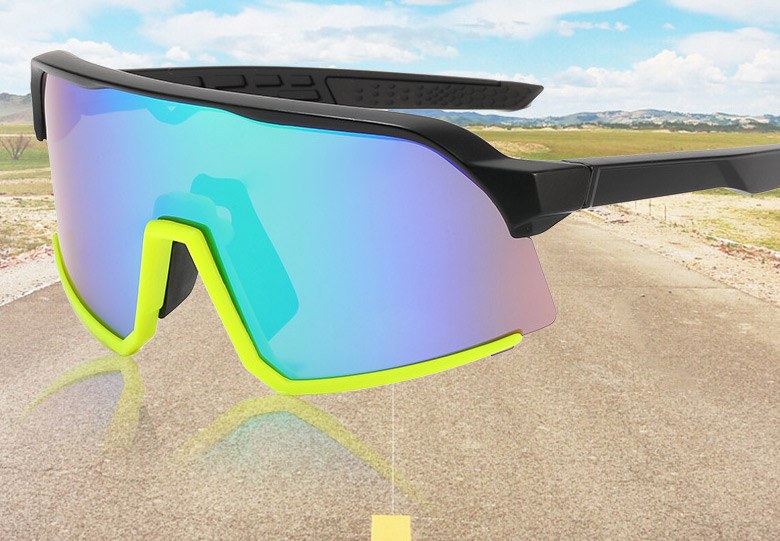

ODM, on the other hand, means the manufacturer designs the sunglasses, and you customize them with your branding. This is a faster, more cost-effective option for brands looking to enter the market quickly without investing heavily in design. For instance, you might choose a pre-designed Sporty Wraparound Sunglasses model and add your logo or tweak the colors—ODM makes it straightforward.

Pros and Cons of Each

- OEM Pros: Complete creative control, unique products that stand out in the market.

- OEM Cons: Higher costs, longer timelines, and a need for design expertise.

- ODM Pros: Quicker production, lower upfront costs, perfect for beginners.

- ODM Cons: Less originality, as other brands may use similar base designs.

Which Should You Choose?

Your decision hinges on your brand’s priorities. If you’re building a premium label with a distinct identity, OEM offers the flexibility to innovate. If speed and affordability are key, ODM lets you hit the ground running. Industry expert Jane Chen, CEO of VisionCraft, advises, “OEM is best for brands with a clear, unique identity, while ODM suits newcomers testing the market without overcommitting.” For deeper insights, check out What to Look for in Reliable Eyewear Manufacturers.

Defining Your Brand’s Needs and Vision

Finding the right manufacturer starts with a clear understanding of your brand’s goals. A well-defined vision ensures you partner with someone who can deliver products that match your identity and appeal to your audience. Here’s how to clarify your needs in three steps.

Identify Your Target Audience

Who are you selling to? Fashion-conscious teens, active outdoor enthusiasts, or luxury buyers? Your audience shapes your product requirements. For example, if you’re targeting kids, you’ll need a manufacturer experienced in safe, playful designs like Heart Shape Kids Sunglasses. Learn more in How to Create Kids Eyewear Safely.

Set Product Goals

What’s the purpose of your sunglasses? Are they fashion accessories, protective gear, or both? Define must-have features like UV protection, polarization, or eco-friendly materials. If sustainability matters, prioritize manufacturers offering options like those discussed in Why Recycled Plastic Sunglasses Are the Next Big Thing. For performance-driven designs, consider Multi-Colored Polarized Sport Sunglasses.

Clarify Your Brand Identity

Your brand’s personality—trendy, affordable, or upscale—should shine through your products. A manufacturer like GM SUNGLASSES, renowned for fashionable designs, suits style-focused brands. For a luxury vibe, opt for premium finishes like those in Metal Sunglasses. Aligning your identity with their capabilities ensures a cohesive product line.

By nailing down these elements, you’ll communicate effectively with manufacturers and find one that brings your vision to life. This clarity sets the stage for a strong partnership.

Sunglasses Types and Market Trends

To pick the right manufacturer, you need to understand the types of sunglasses available and the trends shaping the market. This knowledge ensures your products meet consumer demand and stay competitive.

Popular Sunglasses Types

Different styles require specialized manufacturing skills. Here are some key categories:

- Aviators: Metal frames, precise lens cutting (e.g., Metal Sunglasses on Tree).

- Wayfarers: Acetate frames, expertise in injection molding.

- Sports: Durable TR90 materials, like Cycling Sports Sunglasses.

- Round: Retro-inspired, versatile materials (e.g., Round Sunglasses).

Current Market Trends

The sunglasses industry is evolving with these trends:

- Customization: Personalized features are in demand, as highlighted in 2024 Sunglasses Trends for Women.

- Sustainability: Eco-friendly materials are gaining traction—see Eco-Friendly Biodegradable Sunglasses Complete Guide.

- Polarization: Consumers increasingly favor glare-reducing lenses, boosting polarized options.

Market Stats

In 2023, non-polarized sunglasses held a 78.3% market share, but polarized designs are growing fast. Sports sunglasses account for 30% of the premium segment, signaling a lucrative niche. Staying ahead of these trends helps you choose a manufacturer equipped to meet current and future demands.

Customization: Differentiating Your Brand

In a saturated market, customization is a powerful way to stand out. It lets you craft sunglasses that reflect your brand’s uniqueness and cater to specific customer preferences. Here’s how to make it work.

Why Customization Matters

Consumers love personalization—studies show it can increase brand loyalty by up to 30%. Offering tailored features like frame colors, lens tints, or logo placement can differentiate your brand. For example, Butterfly Sunglasses with custom engravings can attract style-savvy buyers.

Popular Customization Options

Consider these personalization ideas:

- Frame Colors and Materials: Bold hues or sustainable bamboo.

- Lens Tints: Gradient, mirrored, or polarized for flair and function.

- Branding: Logos on temples or lenses.

- Packaging: Unique cases that elevate the unboxing experience.

Get inspired by 10 Hottest Sunglasses Styles for Men 2024.

How to Implement Customization

Partner with a manufacturer offering flexible design options. GM SUNGLASSES, for instance, provides end-to-end customization, from initial sketches to final packaging. Share your concepts early and request prototypes to ensure they match your vision.

Customization not only meets customer expectations but also creates a memorable brand experience that drives repeat business.

Quality Assurance Through Sample Testing

Quality is paramount in eyewear. Substandard sunglasses can harm your reputation and your customers’ eyes. Sample testing is a vital step to ensure your manufacturer delivers excellence.

Why Sample Testing is Essential

Testing lets you confirm:

- UV Protection: 100% UVA/UVB blockage is non-negotiable.

- Durability: Frames and lenses should resist wear and tear.

- Optical Clarity: Lenses must be distortion-free.

- Fit and Comfort: Adjustable features for all-day wear.

Learn more in How Eyewear Quality Inspection Can Put Your Brand on Top.

How to Conduct Sample Tests

- Request Multiple Samples: Assess consistency across batches.

- Test UV Protection: Use a UV meter or lab services.

- Check Durability: Simulate real-world use—drop tests, bending frames.

- Evaluate Comfort: Have team members wear them for hours.

Standards to Look For

Look for compliance with standards like ANSI for UV protection and shatterproof materials. GM SUNGLASSES meets FDA and CE benchmarks, ensuring top quality.

Thorough sample testing protects your brand and guarantees customer satisfaction.

Budgeting and Cost Breakdown

Understanding manufacturing costs is key to setting a realistic budget and pricing strategy. Here’s a detailed look at what to expect.

Manufacturing Costs

Costs per pair depend on materials and complexity:

- Plastic Frames: $5-$10

- Metal Frames: $10-$15

- Acetate Frames: $15-$20

- Custom Designs: Add $20-$50 per design

High-quality sunglasses typically range from $10-$19 per pair, per How Much Does it Actually Cost to Make Sunglasses?.

Additional Expenses

Factor in:

- Minimum Order Quantities (MOQ): Larger orders lower per-unit costs but require more upfront investment.

- Shipping: Air freight (10-15 days) vs. sea freight (up to 2 months).

- Design and Branding: Logos, packaging, and marketing materials.

Profit Margin Potential

Luxury brands often sell sunglasses for hundreds of dollars, showing the profit potential. Smart cost management balances affordability with healthy margins.

For more, see Is Importing Sunglasses Worth It?.

Essential Features to Prioritize

To create bestselling sunglasses, focus on features that resonate with consumers. Here’s what to prioritize.

UV Protection

A non-negotiable: 100% UVA/UVB blockage. Per Trovelle, 90% of buyers prioritize this.

Lens Quality

Clear, distortion-free lenses are essential. Polarization, as in Panoramic Sports Sunglasses, reduces glare—a big plus for sports models.

Frame Durability

Lightweight, sturdy materials like acetate or metal ensure longevity. Compare options in Metal Sunglasses vs Plastic Sunglasses: Which is Better?.

Style and Fit

Match your brand’s aesthetic and ensure comfort. Oversized Sunglasses are trendy but need proper proportions.

These features create sunglasses that look great and perform well, boosting customer loyalty.

Production Timelines and Logistics

Timing is critical in retail. Mastering production timelines and logistics keeps your supply chain efficient.

Typical Turnaround Times

Production varies by order size and manufacturer, with expedited options available for a fee, per Pietra Studio.

Shipping Logistics

Overseas shipping options:

- Air Freight: 10-15 days

- Sea Freight: Up to 2 months

Plan for sales seasons—see How to Start Your Sunglasses Business: Import from China.

Inventory Planning

Align production with sales forecasts to avoid stock issues. A partner like GM SUNGLASSES can streamline this process.

Effective planning ensures you meet demand without delays or overstock.

Why Manufacturer Customer Service Matters

A manufacturer’s customer service can define your experience. Here’s why it’s vital.

Clear Communication

Responsive support resolves issues fast, avoiding costly setbacks. iDetail Eyewear emphasizes the value of professional liaisons.

Ongoing Support

From design to delivery, reliable service enhances trust. GM SUNGLASSES offers 24/7 assistance for seamless collaboration.

Building Trust

Quality service fosters long-term partnerships, supporting your brand’s growth.

Prioritizing customer service ensures a smooth, successful manufacturing process.

Steps to Find and Vet Manufacturers

Here’s how to locate and evaluate manufacturers effectively.

Where to Look

- Online Platforms: Explore Pietra Studio.

- Trade Shows: Visit events—see Eyewear Trade Shows: The Ultimate Guide.

- Referrals: Ask industry peers for trusted contacts.

Vetting Process

- Request Samples: Test quality and consistency.

- Check Certifications: Look for ISO 9001 or similar standards.

- Visit Factories: Or request video tours.

- Ask for References: Verify past client experiences.

More tips in 10 Best Practices to Ensure Quality Eyewear Imports.

These steps help you find a manufacturer that aligns with your goals.

Legal and Ethical Compliance

Compliance protects your brand’s reputation and customer trust. Here’s what to consider.

Regulatory Compliance

- UV Protection: Must meet ANSI or equivalent standards.

- Material Safety: Avoid harmful substances—see Do All Sunglasses Have Prop 65 Warning?.

Ethical Practices

- Fair Labor: Ensure ethical worker treatment.

- Sustainability: Use eco-friendly materials to appeal to conscious consumers.

Intellectual Property

Secure your designs with contracts to prevent copying. Learn more in How to Find Reputable Chinese Sunglasses Manufacturers.

Compliance builds a trustworthy, ethical brand.

Industry Insights and Future Outlook

Staying informed positions your brand for success. Here’s the latest.

Market Growth

The sunglasses market is set to grow at a 5.6% CAGR through 2030, fueled by fashion and health trends.

Emerging Trends

- Eco-Friendly Materials: Biodegradable options are rising.

- Personalization: Custom features gain popularity.

- E-Commerce: Online sales offer new avenues.

Explore more in 2021 Fall/Winter to 2022 Spring/Summer Sports Sunglasses Trends.

Aligning with these trends ensures long-term growth.

Conclusion

Choosing an expert sunglasses manufacturer is pivotal to your brand’s success. This guide has covered it all—OEM vs. ODM, defining your needs, market trends, customization, quality testing, budgeting, and compliance. With these insights, you’re ready to find a partner that delivers exceptional products.

GM SUNGLASSES stands out as a reliable choice, offering nearly a decade of expertise, global reach, and a commitment to quality. Ready to bring your vision to life? Contact GM SUNGLASSES today to start crafting your perfect eyewear line.